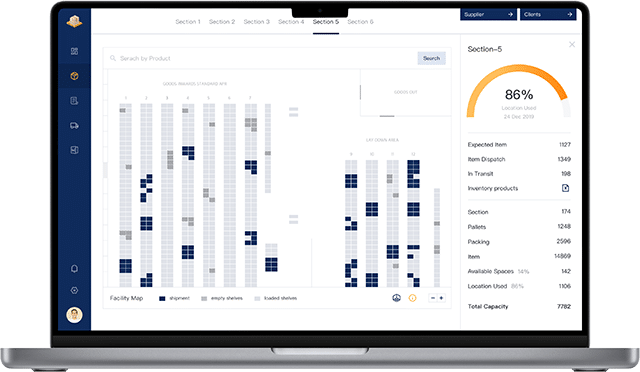

A robust warehouse management system (WMS) is a smart warehousing technology that is the centerpiece of this digital ecosystem, helping employees handle the entire scope of warehouse processes, starting from the time products are delivered there up to the moment when they move out in their outbound shipments. Custom WMS software leveraged by multiple warehouses allows them to attain a high degree of warehouse automation and essentially streamline and facilitate all pipeline business operations.

Our custom warehouse management systems development services

The warehouse management solutions we craft enable organizations to manage warehouse operations throughout the end-to-end cycle of their shop floor routine in this field.

Fleet management software development

A custom fleet management solution tailored specifically to the needs, goals, values, and other underlying attributes of your business is a real game-changer in the times of templated e-commerce and supply management systems. A solution like that will ultimately boost your long-term RoI, fleet productivity, user data and BI security, scalability, and demand tendencies. With proper expertise and enough experience like we possess at DICEUS, we can build something truly unique, created from scratch individually for your brand.

Logistics data analytics and reporting

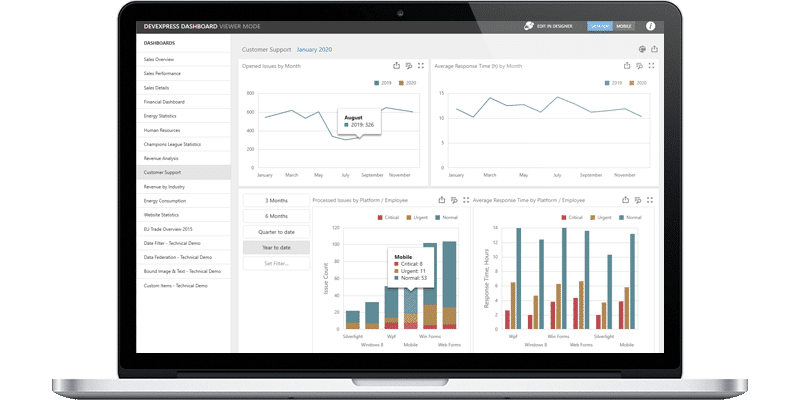

In terms of fleet management system development at DICEUS, we prioritize in-depth work with data, focusing on thorough data analytics and reporting when it comes to logistics. Well-optimized, calibrated logistics result in the ultimate long-term success of the supply chain you maintain. We will help you outline the best new routes based on the statistical and historical data (as well as other logistics data) to save more essential costs and bear less unnecessary expenses through specialized integrations.

APIs and software integration

A fitting API properly integrated with the supply chain or fleet management system enables extensive optimization, performance, productivity, and connectivity opportunities. We have the expertise to build and integrate solutions that ultimately centralize and interconnect all your supply chain features and tools, both technical and collaborative. Sky’s the limit with the custom fleet management software development approach provided by seasoned specialists with extensive portfolios highlighting outstanding creations across industries.

IoT solutions for fleet management

To add an innovative touch to how you usually handle things and expand the efficiency of your supply chain and fleet performance even further, we create IoT solutions for fleet management. Using metrics-generating beacons and sensor devices firmly connected to the real-time data processing centralized network does wonders in terms of managing widespread fleet points. On top of that, the Internet of Things presents one of the trendiest toolsets, which will also make a great push for your marketing efforts and brand recognition.

WMS mobile apps

Traditionally, warehouse managers spent the lion’s share of their office hours at their desks. We can create a bespoke WMS product that will allow them to get down to warehouse workers and direct their operations on the floor with the help of mobile devices. Besides, our high-performance and elegant applications will become a pivotal tool for rank-and-file employees who will leverage them in multiple workflows (inventory levels tracking, supply chain operations, warehouse space utilization, barcode scanning, you name it) from any location.

WMS implementation

Having a finished WMS product delivered to their doorstep, many companies still struggle with its enterprise-wide implementation. Vetted experts of DICEUS will be there to put the newly created system into operation root and branch. They will give a helping hand in defining the implementation strategy, cleaning and curating your data, testing the solution’s functioning in real-world conditions, training personnel who will utilize it, launching the system, monitoring and fine-tuning its operation, and ensuring real-time visibility across all implementation stages.

Want to get a project roadmap and recommended tech stack?

Benefits of our warehouse management software services

The contemporary IT outsourcing market is full of vendors offering their services to the global entrepreneur audience. What makes DICEUS stand out among the rest as the right developer choice for your WMS project?

Must-have features for custom warehouse management systems

Depending on the specifics of your organization, we can fill the custom WMS we are going to build for you with any functionalities your pipeline routine requires. The typical roster of characteristics ensuring the system’s efficient operations includes:

- Inventory control. Inventory management systems are the core of WMS solutions, allowing companies to keep track of the organization’s inventory in real-time and monitor item receiving, packing, labeling, storing, replenishment, shipping, and the like. Equipped with barcode scanning capabilities, such tools provide inventory accuracy, alert personnel dealing with dangerous or temperature-sensitive goods, forestall stockouts, and watch out for overstocking.

- Location management. This feature excels at identifying and classifying space within the warehouse and creates its digital map where storage locations, aisles, columns, shelves, and special zones (high security, chilled, frozen, etc.) are outlined. To meet customer demand, we can equip this module with multiple warehouse integration capabilities.

- Order management. It enables warehouses to handle orders from multiple internal and external partners, provide inventory status and dispatch updates for them, manage orders in bulk, keep track of order details, observe order statuses, boost order picking and packing routine, automate task assignment depending on location and priority, and more.

- Supply chain management. Smooth movement of supplies is the blood circulation system of the complex warehouse organism. This functionality of WMS allows employees to implement complete traceability of goods across numerous locations, streamline delivery coordination, and facilitate carrier management (including carrier selection, delivery scheduling, and performance monitoring).

- Shipping management. Such transportation management systems help organizations strategically organize and manage dock space allocation, optimize goods loading and unloading, streamline load verification, improve route planning, minimize fuel consumption, reduce carbon footprint, and cut down on labor costs.

- Document management. This capability allows organizations to avoid excessive paperwork in their shop floor operations, switch over to digital document flow, automate the generation, approval, and distribution of documentation, and usher in digital contract management, where digital signature functionality reigns supreme.

- Returns management. Using this module, warehouse personnel can generate any relevant document, log the returned product, register reasons for the return, inspect the item to determine whether it will be restocked or scrapped, and provide a refund or exchange option to the client. In this way, increased customer satisfaction is guaranteed.

- Financial management. Handling all financial documentation is a breeze with this functionality. Especially useful is its ability to automatically generate invoices. Besides, it can calculate inventory costs and costs of sold products by tracking purchases, sales, adjustments, and other inventory movements.

- Reporting and analytics. When reinforced with artificial intelligence, this feature allows employees to obtain KPI reports, thanks to which they can monitor and analyze operational metrics. Such data becomes valuable insights, enabling informed decision-making and predictive analytics related to inventory planning and demand forecasting.

- Integrations. A WMS system can bring maximum value only when synchronized with ERP, CRM, and other components of the organization’s IT infrastructure. By ensuring its synergy with the entire digital environment via an open API, you provide the system’s compatibility with multiple resources and platforms, avoid data silos, and maintain business consistency and continuity.

Our WMS development process

DICEUS’s qualified and certified professionals have more than a dozen years of experience in delivering high-end enterprise solutions for the retail and logistics industries, which has allowed them to devise an efficient algorithm for tackling such projects.

About DICEUS

Get professional consulting on your project!

What impacts your project duration

There is no standard timeframe when it comes to the custom development of a WMS system: each project is unique. Nonetheless, some common factors have a substantial impact on the duration of your project.

- Project requirements

- Expected time-to-market

- Team composition

- Chosen platforms and technology stack

- Integration needs

What affects your project costs

The cost of every WMS development project is as individual as its duration. The following factors determine the final cost of your WMS solution:

- Project scope and complexity

- Chosen technology

- Project completion urgency

- Engagement model: Time and Material, Dedicated Team

What we need from your side

To achieve the best possible results in terms of both project duration and cost efficiency, we always do our best to make an SDS appear as soon as possible. The following info (if available) can significantly facilitate our efforts:

- Project goals, vision, and roadmap, if exist

- High-level project requirements

- Project-specific documentation,n if available, for example, software architecture and mockups

- Client’s availability (a couple of hours per week for requirements gathering sessions)

- Project deadlines

Our tech stack

Explore our custom warehouse management systems development case studies

Frequently asked questions

What are the most popular WMS solutions globally?

One of the burning trends in logistics these days is 3PL (third-party logistics) when inventory, warehousing, and fulfillment are outsourced to some third-party vendors. They usually use the following 3 types of WMS systems: integrated ERP, supply-chain modules, and standalone WMS. Some of the leading ready-to-use systems are NetSuite WMS, Fishbowl Inventory, Softeon, and HighJump. Even though they are represented as out-of-the-box WMS solutions, it is necessary to select the business specialization inherent in each system: wholesale, manufacturing, 3PL, e-commerce, and the like.

What are the essential features of WMS systems?

The functionalities of custom WMS systems may significantly vary according to the domains where they have to work. However, any application that claims to be a fully functional WMS solution can hardly do without the following features: Inventory tracking, pick-and-pack processing, task management, shipment scheduling, order fulfillment, data collection, accounting, reports, and notifications.

What are the benefits of warehouse management apps?

Enhanced productivity due to optimized warehouse operations is widely considered as the main advantage of WMS system implementation. Automation of inventory leads to faster and more precise movements of goods along the entire supply chain. The improved deliveries result in stronger customer loyalty along with a higher retention rate. Transport drivers benefit from better cross-docking and faster loading. And finally, your employees become happier with improved workflows and demonstrate better performance along with lower staff turnover.